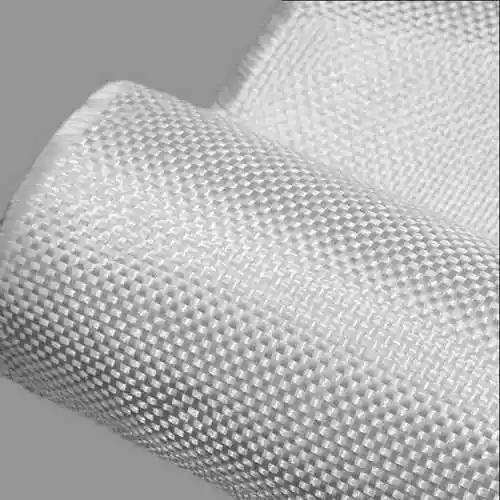

Glass fiber fireproof cloth protects buildings. It can stop fires from spreading or burning. During construction, we must use key techniques to ensure quality.

Site Cleaning

Clear the site of garbage and debris. This ensures safety and smooth progress in the construction. Next, measure the wall area. Then, calculate the fireproof cloth needed. This will avoid waste or shortages.

Material Laying

Material Laying

You need to lay the glass fiber fireproof cloth on the wall. During the laying process, check the fireproof cloth. It must be flat and tight. The fabric must have a strong adhesion to the wall. Also, the fabric’s overlap must not exceed 10 mm. It may affect the effect.

Coating Treatment

The coating’s job is to improve the fireproof cloth’s fire resistance and appearance. Before coating, you need to sand and clean the wall to ensure the adhesion and flatness of the coating. Apply the fireproof coating in a uniform layer on the cloth. The coating should be no more than 1 mm thick.

Inspection and Acceptance

Check the fireproof cloth’s resistance to fire. Also, check the coating’s adhesion and thickness. This is to ensure the construction meets quality standards. Only after passing the acceptance test can we put it into use.

Making glass fiber fireproof cloth needs careful attention to detail. This focus is key to ensuring quality and effectiveness in the construction process. Only strict construction and inspection can prevent fires and protect buildings.

Hongwo Thermal Insulation Material

Hongwo Thermal Insulation Material

Material Laying

Material Laying